Evercross Equipment

1.Brief introduction

Heavy-Duty Container Roller Movement Set for Shelters (hereinafter referred to as Container Movement Set) is developed for moving standard shelters or objects with standard angles, easy to operate and move.

It is used for short-distance movements of objects container、shipping container.

There shall be 4 persons for installation and roll-up.

2. Performance Index

1. The container movement set is used for lifting and moving the heavy-duty container.

2. Hydraulic system can be locked reversely, in order to preventing the shelters or transportation containers from falling down.

3. It can be put in place reliably after loading containers

4. It is suit for 40ft and 20ft standard container.

Compositions

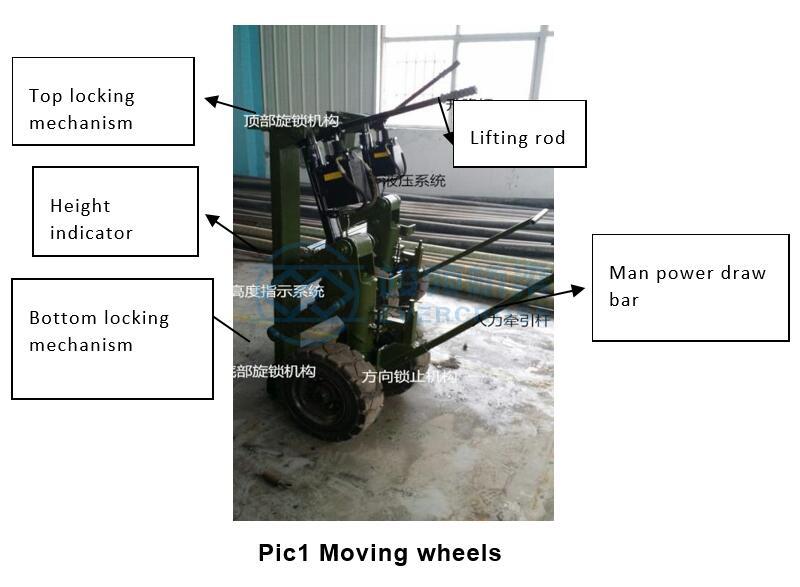

The composition of the equipment is as shown in pic1, pic2

|  |

Table2 part list of transportation equipment

Serial number | Parts name | Type | Qty | remark |

1 | Moving wheels | Saem-611-01 | 4 |

|

2 | Lifting rod | Saem-611-02 | 1 |

|

3 | Hydraulic system | Saem-611-03 | 4 |

|

4 | Cross rod for vehicle traction | Saem-611-04 | 1 |

|

5 | Drag rod for vehicle traction | Saem-611-05 | 1 |

|

6 | Direction arm for vehicle traction | Saem-611-06 | 1 |

|

7 | Manual drawbar | Saem-611-07 | 1 |

|

8 | Height indicator system | Saem-611-08 | 1 |

|

9 | Direction locking mechanism | Saem-611-09 | 1 |

|

10 | Bottom locking mechanism | Saem-611-10 | 1 |

|

11 | Top locking mechanism | Saem-611-11 | 1 |

|

12 | Positioning device | Saem-611-12 | 2 |

|

Operation method

Check before use

Step1: Check the main part of Container Movement-hydraulic pump, whether the hydraulic oil meets requirements, the resistance of hydraulic rod is right for moving up and down, check whether the hydraulic system is oil leak and loose. The hydraulic system shall be operated after finishing inspection.

Step2: Check the oil valve of hydraulic pump in level ground. The level of oil cannot be lower than the center of sight flow glass, forbidden using with a little oil or without oil.

Step3: Count the components of container movement, the components details see table2 《part list of roller movement》.

Step4: Open the locking mechanism of two forwarding moving wheels. Move a full set of container movement near to the container, and put it in steady place, lock moving wheels mechanism, insert the king pin, in order to keep steady for further usage.

Fault diagnosis and troubleshooting

Table3 The exclusion of common faults

Fault conditions | Fault phenomenon and reason | Elimination method |

No pressure | Pump could not suck the oil | Fuel tank, Change the filter |

The assembly of pump is not appropriate, the pump is not work, is dirty. | Repair or replace | |

Insufficient pressure | Pump or fluid cylinder is damaged, and Internal leakage. | Replace or repair |

The tank level low | Oil to the labeled Height | |

Cylinder does not work | Fuel tank without oil | Add the hydraulic oil |

The seal of the hand pump is damaged, Oil pressure is not promoted. | Dismantle the manual pump, | |

Replace seals | ||

Cylinder without rod,oil pipe is loosen | Screwed pipe joint | |

The piston rod oil | The seal components for the front of the oil cylinder are wear and tear. | Remove cylinder rod end seal |

Joint leakage | The pipe joint is loose | Tighten the joint |

Sealing washer of the joint is damaged. | Replace sealing washer | |

Serial number | Parts name | Type | Qty | remark |

1 | moving wheels | Saem-611-01 | 4 |

|

2 | lifting rod | Saem-611-02 | 1 |

|

3 | hydraulic system | Saem-611-03 | 4 |

|

4 | cross rod for vehicle traction | Saem-611-04 | 1 |

|

5 | drag rod for vehicle traction | Saem-611-05 | 1 |

|

6 | direction arm for vehicle traction | Saem-611-06 | 1 |

|

7 | manual drawbar | Saem-611-07 | 1 |

|

Certified

Certified