Floating Pontoon Bridge

Description:

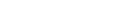

1.Floating pontoon bridge refers to a bridge that floats on the water surface with a boat or pontoon tank instead of bridge piers. The floating pontoon bridge is composed of floating pier, panel, distribution beam and cable air system.

2. Floating pontoon bridge design basic scheme consideration points

Road condition, performance, pontoon structure, pontoon drawings, environment

3. Basic design principle of floating pontoon bridge

Principles to be followed: the performance objectives are consistent with the purpose, safety, durability, quality, ease of maintenance and management, harmony with the environment, economy and other indicators.

Choosing the type of structure: topographic, geological and geographical conditions should be considered.

The number of pontoon structures and the overall system should meet the requirements of strength, deformation and stability.

The service life of a floating pontoon bridge is very sensitive to environmental conditions and factors such as natural loads (such as wind, water waves, current, tidal changes, sub-fluctuations in the lake surface) and corrosion. Under the condition of low cycle cost, the service life of the floating pontoon bridge is generally expected to be 75-100 years.

According to the classification of importance, the floating pontoon bridge is divided into standard type and special important type, that is, type A floating pontoon bridge and type B floating pontoon bridge. Floating pontoon bridge A is different from floating pontoon bridge B. B floating pontoon bridges are divided into: expressways, urban expressways, designated urban roads, ordinary national roads, double crossings, viaducts, railway Bridges, especially important local and municipal bridges.

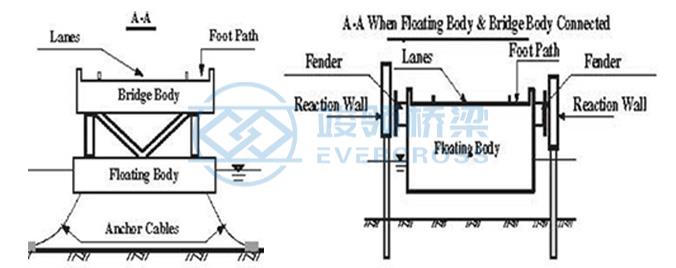

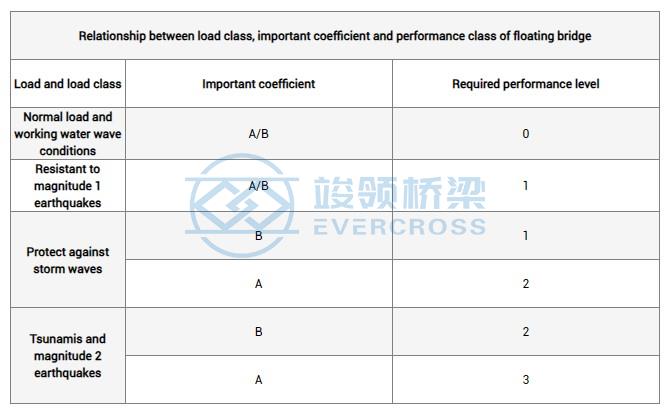

Below table gives the classification of the status performance levels of the floating pontoon bridge. A state performance level of 0 is mainly compared to other performance levels 1-3. For traffic loads, storm waves, tsunamis and earthquakes, the pontoons are designed in several performance levels.

According to the importance factor, the design of the floating pontoon bridge should ensure that it has the corresponding target performance level listed in Table 7, such as load, storm wave, tsunami and earthquake.

4. Floating pontoon bridge design load

Design load

It mainly includes: Static load, dynamic load, impact load (such as collision, etc.), earth pressure (such as the anchor pile in the anchoring system on the floating pontoon bridge), hydrostatic pressure (including buoyancy), wind load, water wave factor (including expansion factor), seismic factor (including hydrodynamic pressure), temperature change factor, water flow factor, tidal change factor, foundation deformation factor, support movement factor, etc. Snow load, centrifugal load, tsunami factor, storm tide factor, lake fluctuation (secondary fluctuation), ship shock wave, sea shock, braking load, assembly load, collision load (including ship collision), pack ice factor and pack ice pressure, coastal transport factor, drifting object factor, water class factor (erosion and friction) and other loads.

Buoyancy, water wave, wind and recurrence period

During the design of the floating pontoon bridge, the water level change caused by tide, tsunami and storm surge is one of the control loads. The vertical axis of the floating pontoon bridge should be considered in the design. When the wind blows over the water, the resulting waves will create horizontal, vertical and torsional loads on the floating pontoon bridge. These loads depend on wind speed, direction, duration, blow length (wind zone length), channel structure and depth.

The design wind speed is the average speed over a 10-minute period at an altitude of 10m above the water. Natural loads such as winds and earthquakes are a key factor in many cases.

Irregular water wave

Normally, water waves are very irregular. They are composed of regular water waves with many frequency components.

Because the natural period of the floating pontoon bridge is much longer than that of the traditional bridge, the effect of water wave with long period is greater. In terms of frequency, the spectrum represents the energy distribution of water waves. When the wind blows from a certain horizontal distance, the water waves continue to travel. But after a certain period of time, the water wave stops gradually strengthening and becomes stable.

Combined load

The combined load will have an adverse effect on the floating pontoon bridge.

Tide levels are divided into the following categories:

During earthquakes: between H.W.L.(high water level) and L.W.L.(low water level);

During snowstorms: between H.H.W.L.(highest H.W.L.) and L.W.L. or between H.H.W.L. and L.L.W.L.(lowest L.W.L.);

Conditions of use: between H.W.L. and L.W.L.

Thus, no fatal damage occurs during tsunamis, either from extreme tidal changes between H.W.L. and L.W.L. or from rising and lowering water levels.

5. Floating pontoon bridge material

Common materials are steel and concrete.

Generally speaking, the corrosion of the pontoon structure should be considered first. Because the watertightness of concrete is very important, watertight concrete or marine concrete is generally used in the manufacture of floating pontoon bridges. Among them, medium melting Portland cement, Portland blast furnace slag cement, Portland flying dust cement can be used to make floating pontoon bridges. The peristalsis and contraction effects of the structure need to be considered only when the tank is dry, so the above effects do not need to be considered once the tank is launched. High performance concrete such as fly dust and silica powder is most suitable for making floating tanks.

The materials used in the mooring system should be selected according to the design objectives, environment, durability and economy.

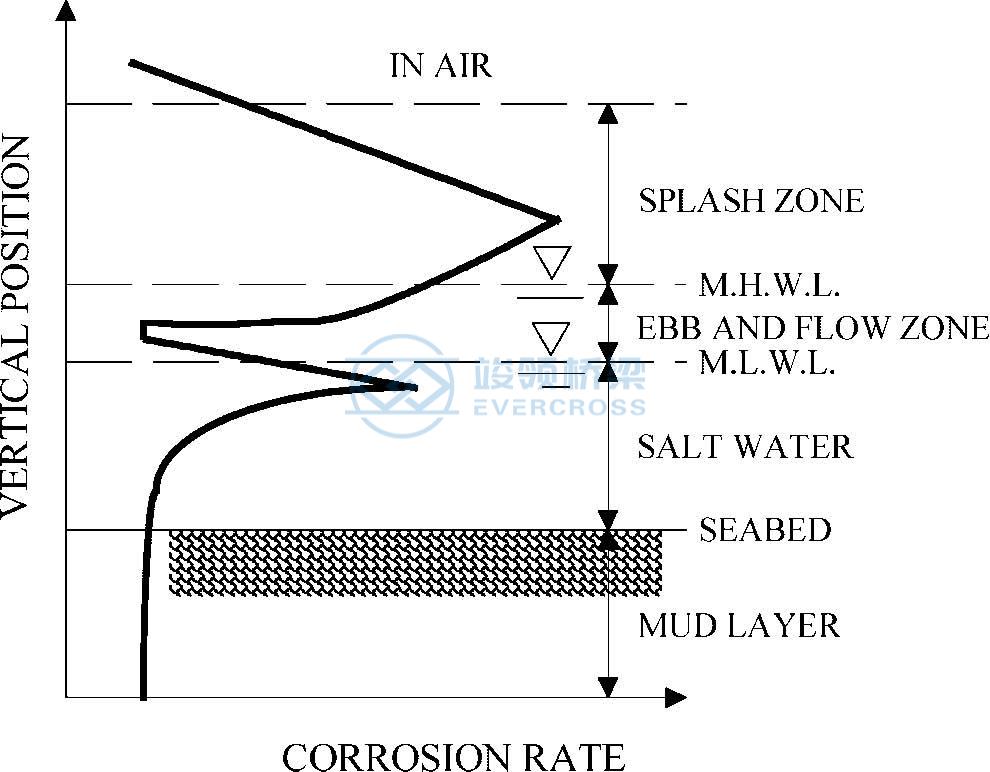

Due to the corrosive environment, anti-corrosion is necessary, especially in the parts below the average water level, M.L.W.L., there will be serious local corrosion. For such parts, cathodic protection is generally adopted.

Surface treatment is generally adopted under L.W.L. surface treatment methods include painting, adding organic material surface, mineral grease surface, inorganic material surface and so on. Inorganic surface treatment includes metal coating, such as titanium coating, stainless steel surface, zinc, aluminum, aluminum alloy, etc. The effect of water depth on the rate of corrosion depends on the environment.

Splash corrosion is the most serious, and its upper limit can be determined according to the installation of the structure.

The ebb and flow area is the most severe environment, and the corrosion rate varies greatly with the depth.

In the saltwater zone, the environment becomes more moderate. But for some conditions, such as currents and increased shipping, corrosion can be accelerated.

The environment of the soil layer below the seabed depends on salt density, pollution level and climatic conditions, but the corrosion rate is relatively stable.

Note: Compared with the fixed structure, the floating pontoon bridge changes with the water surface, so the ebb and flow of the tide is not existent.

6. Limit state of the floating pontoon bridge

The floating pontoon bridge should be have sufficient capacity to face potential hazards such as ships, debris, wood, floods, mooring rope failure, and complete separation of the bridge after lateral or oblique fracture.

Although the water provides buoyancy for the floating pontoon bridge, if the water leaks into the interior of the floating pontoon bridge, it will gradually damage the floating pontoon bridge and eventually lead to the sinking of the bridge. This is the current research problem facing the floating pontoon bridge.

7. Specific design and analysis of floating pontoon bridge

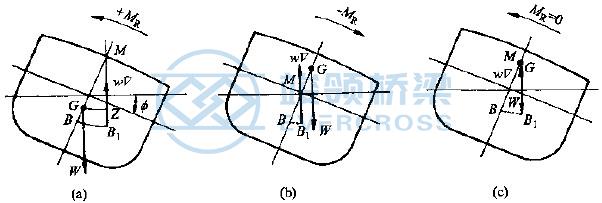

Stability: refers to the ability of the ship to tilt under the action of external forces, and to return to the original balance position after the external forces disappear.

Three equilibrium states:

1) Stable balance: G is under M, and gravity and buoyancy form a stability torque after the tilt.

2) Unstable equilibrium: G is above M, and gravity and buoyancy form an overturning moment after tilting.

3) Accidental balance: G and M coincide, and gravity and buoyancy act on the same vertical line after tilt, without torque.

The relationship between stability and ship navigation:

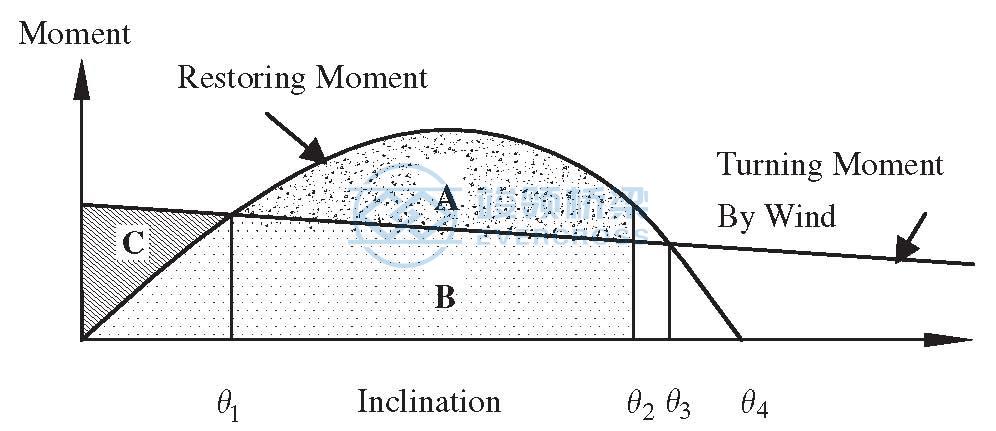

1) The stability is too large, and the ship swings violently, causing discomfort to personnel, inconvenient use of navigation instruments, easy damage to hull structure, and easy displacement of cargo in the hold, thus endangering the safety of the ship.

2) The stability is too small, the ship's anti-capsizing ability is poor, it is easy to appear large inclination Angle, slow recovery, and the ship is tilted on the water surface for a long time, and the navigation is ineffective.

As with boats, the overturning of pontoons is related to their static stability.

In the process of designing a floating pontoon bridge, several most important physical quantities need to be considered: vertical displacement and horizontal displacement and tilt degree.

Whether it is the usual once-in-a-year blizzard weather conditions or the extreme once-in-a-century blizzard conditions, the comfort of traffic needs to be carefully considered in the design. Therefore, the response acceleration of the bridge should be within the range of tolerable values.

Handling stability: Ease of handling is one of the most important performence.

Fatigue: to prevent structural damage caused by dynamic loads, such as wind, water waves, etc. The assessment method is the same as for traditional Bridges.

Seismic factors: Because the floating pontoon bridge has a long natural period, it is necessary to study the influence of long-period seismic waves. Although pontoons are inherently isolated, the resistance of the mooring system to earthquakes needs to be verified, especially the mooring piles and foundations.

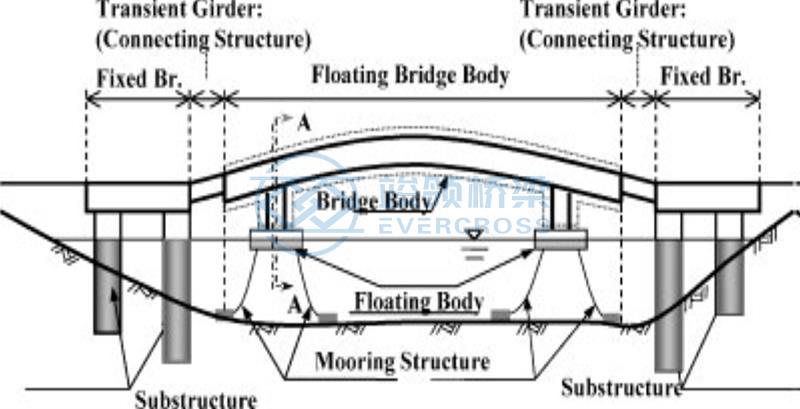

8. Floating pontoon bridge body design: General pontoons mainly consider the separate pontoon tank. As explained earlier, the hydrodynamic characteristics of each tank can be studied individually, and then the results obtained can be used for global system analysis. In fact, discrete methods such as finite element method are often used in global system analysis. For this analysis method, the additional mass of each tank, hydrodynamic damping and hydrodynamic factors should be considered, and the position of the center of buoyancy of the tank should be input.

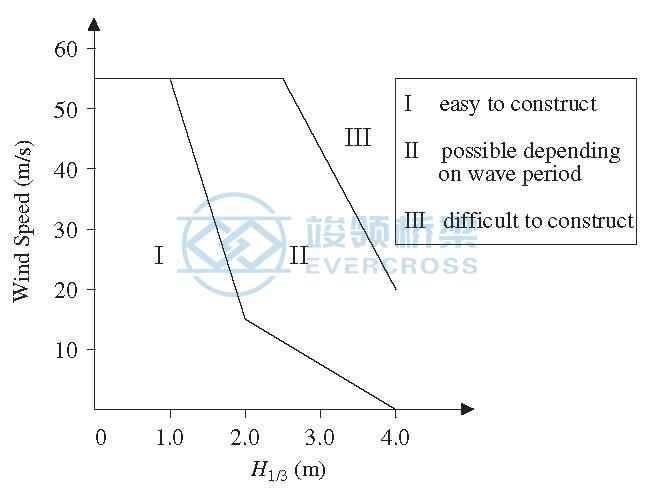

Design of wind speed and effective wave height: the effective wave height of 2.5m is a key point of the pontoon type bridge. In order to ensure that the effective wave height is below 2.5m, it is necessary to set up a wave barrier. The viscous effect and the potential flow effect are two important factors in the analysis of the incident water wave motion and the stress of underwater structures. For potential flow theory, it is mainly the scattering and radiation effects of water waves around the structure.

Scope of application of pontoon type floating pontoon bridge

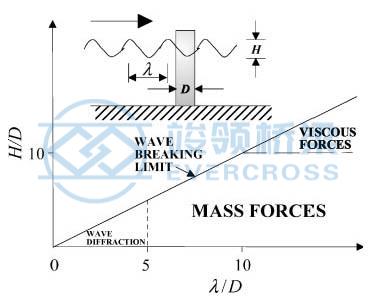

Comparison of mass force, viscous resistance and scattering force

Water scattering is the most important. Therefore, it is very reasonable to apply the scattering theory of water wave to analyze the problem in this region.

In fact, although the free surface fluid potential flow theory is based on the assumption that the fluid is incompressible, irrotational, and non-viscous, its prediction results are in good agreement with the experimental results. This is why water wave scattering theory based on linear potential flow theory is often applied in design analysis.

Superstructure design: mainly includes structure type selection, structure composition design and anti-corrosion content.

Floating body design: The floating body design is very different from the traditional bridge design. Floating body design includes: floating body type selection, floating body flood control part design, ship collision prevention design, transition connection section structure design, corrosion protection, ancillary facilities and anchoring structure design.

Design of anchoring structure: confirm the type, distribution and quantity of anchoring structure. In the design, it is necessary to understand the various parameters of the environment, such as wind speed, water wave and current, earthquake, temperature change, tsunami, lake surface shock (secondary wave), long period water wave, anchor pile anchoring structure design, anchor chain anchoring, tension leg platform and other conditions, and the anchoring method through the two ends of the clamp.

Basic design: basic design usually includes: confirm the load, select the type of foundation.

Accessory design: selection and design of connection structure.

9. Application of floating pontoon bridge: pedestrian, road and railway.

10. Features of floating pontoon bridge: The structure is not complicated,it is also easy to disassemble,but maintenance costs are high.

The purpose of building floating pontoon bridges is generally divided into two categories: one is to meet the needs of military combat readiness or disaster relief. Because the floating foundation replaces the complex underwater fixed foundation, the floating pontoon bridge is easy to set up, easy to dismantle, easier to evacuate and hide, and easier to load and transport, and has outstanding rapidity and mobility.

In wartime, it can overcome river obstacles, guarantee railway and road transportation, in peacetime, overcome flood disasters, carry out rapid repair and disaster relief, or quickly communicate with the two sides to transport various large-scale construction materials, which is a short-term flexible and efficient emergency means, so the theoretical and experimental research on this kind of floating pontoon bridge is of great practical significance.

The other purpose is mainly for economic considerations, namely, when the water depth of the site is very large or the bottom is very soft, the construction of traditional piers is not suitable. At this time, using the natural buoyancy of water, a floating pontoon bridge that does not require traditional piers or good foundations becomes a better choice.

Evercross Steel Bridges Overview:

EVERCROSS STEEL BRIDGE SPECIFICATION | |

EVERCROSS STEEL BRIDGE | Bailey bridge (Compact-200, Compact-100, LSB, PB100, China-321, BSB) |

DESIGN SPANS | 10M TO 300M Single span |

CARRIAGE WAY | SINGLE LANE, DOUBLE LANES, MULTILANE, WALKWAY, ETC |

LOADING CAPACITY | AASHTO HL93.HS15-44, HS20-44, HS25-44, |

STEEL GRADE | EN10025 S355JR S355J0/EN10219 S460J0/EN10113 S460N/BS4360 Grade 55C |

CERTIFICATES | ISO9001, ISO14001, ISO45001, EN1090, CIDB, COC, PVOC, SONCAP, etc. |

WELDING | AWS D1.1/AWS D1.5 |

BOLTS | ISO898, AS/NZS1252, BS3692 or equivalent |

GALVANIZATION CODE | ISO1461 |

Certified

Certified