Steel Box Girder Bridge

Instruction:

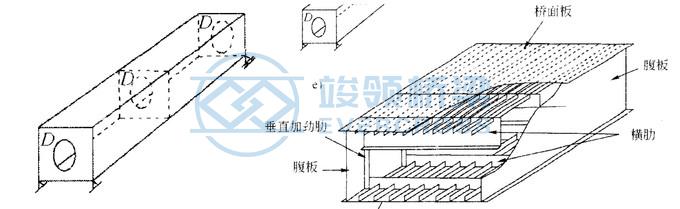

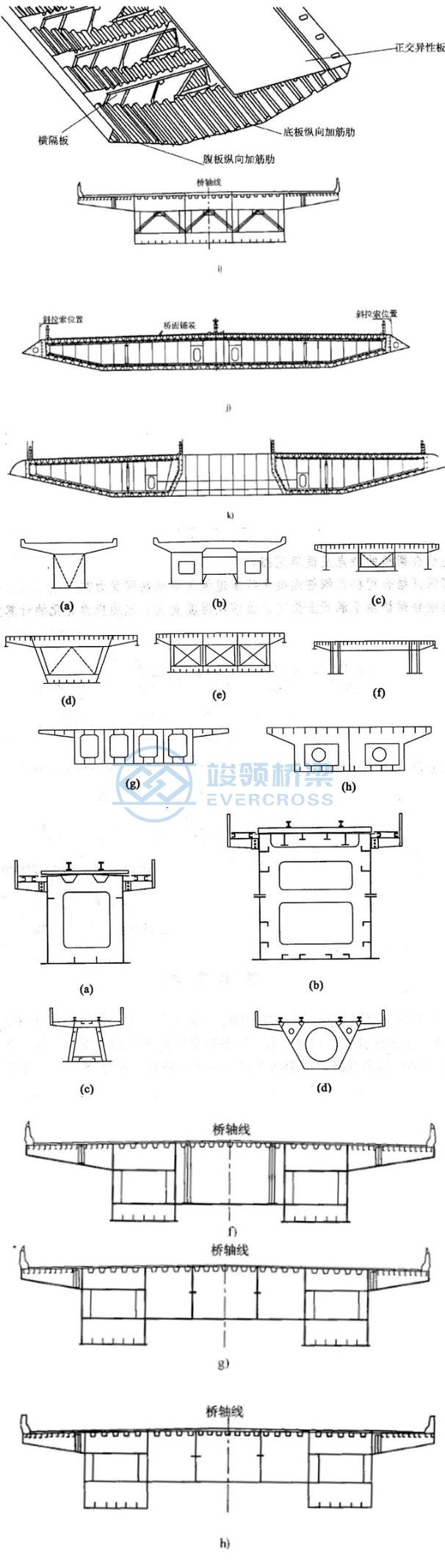

The steel box-girder bridge is generally composed of top plate (bridge panel), beam web, bottom plate, longitudinal stiffener and transverse stiffener, and diaphragm plate (cross beam).

The thickness of the top plate, beam web and bottom plate is generally 12~30mm, and the thickness of the secondary plate is 10~20mm.

Usually adopted manufacturing fragments in factory (section length is generally 10-30m, depending on transportation and hoisting conditions) and site welding.

In order to ensure the quality of welds, welding in factory should be adopted as far as possible, and should strictly check the weld quality.

The lower edge of the top plate is welded with vertical and horizontal stiffeners to form an orthogonal bridge panel. The so-called orthogonal shaped plate means the stiffening rib vertical intersection. Due to the different parameters such as the distance and stiffness of stiffeners, the mechanical properties of the ribs are very different in bridge direction, cross bridge direction, relatively save steel, and is very suitable for bearing local wheel load.

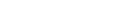

Orthotropic steel bridge panels

The basic forms of longitudinal rib section are open and closed.

The cross-section form of the ribs is usually inverted T shape, and its spacing is the span of the longitudinal ribs. In order to enable the longitudinal ribs to pass through continuously, the transverse ribs should be provided with notches.

Box girder is not only the main beam form of beam bridge, but also the main beam form often other long-span bridges, such as suspension bridge and cable-stayed bridge.

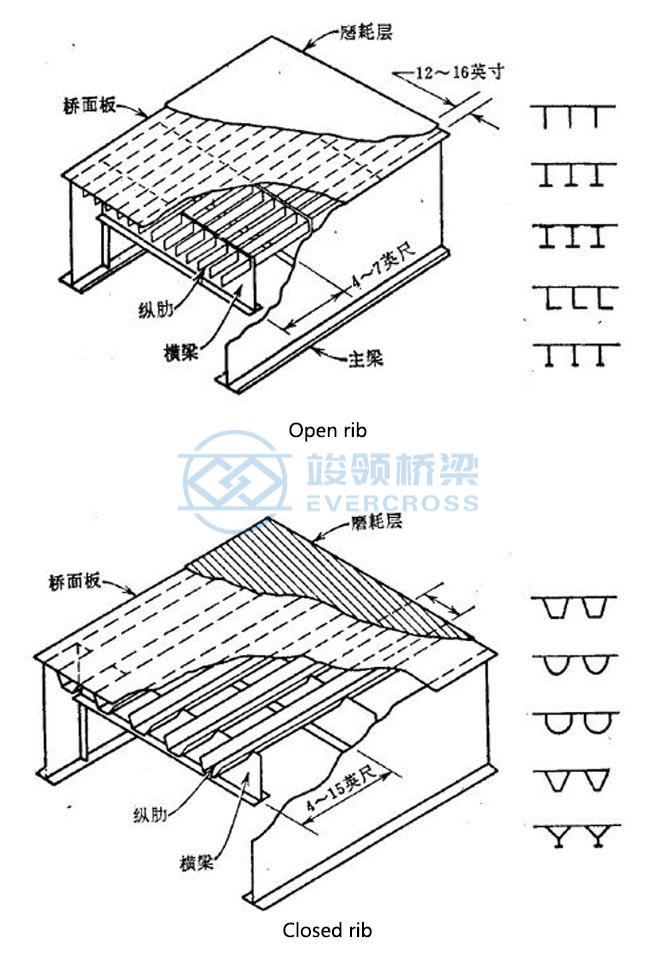

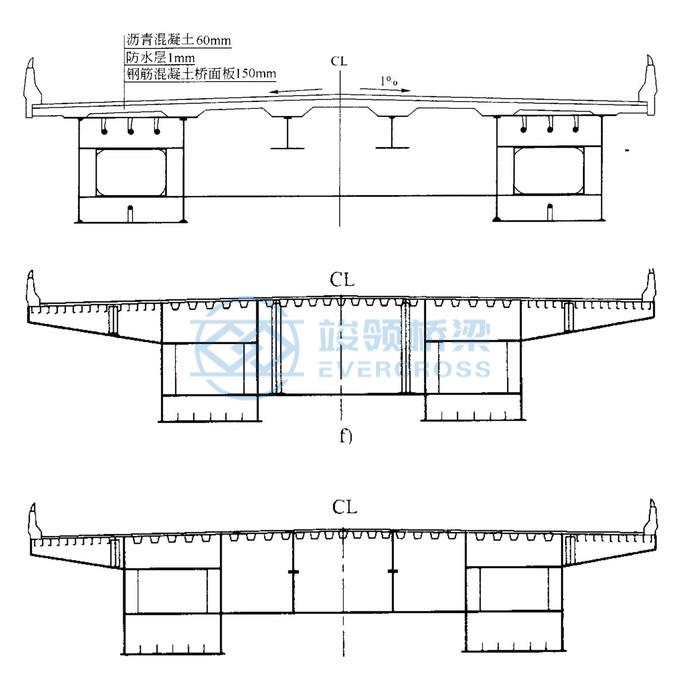

Structural form of steel box-girder bridge

Single box steel beam bridge

Scope of application: when the bridge width is small (3 lanes) or width to span ratio <1/10

For 4~6 lanes, double width single box girder bridge can be adopted.

Effective flange width: main beam web interval <=Le/5

Main beam cantilever length <=Le/10

Beam lifting: When the reinforced concrete bridge floor is long and the cantilever is long, the lifting beam and the side beam should be set up, and the corresponding transverse partition or transverse rib should be set up.

Beam: steel deck, which can improve the stiffness of the bridge panel, spacing 1.5m~3m (open rib)

Interval: 2m~4m (closed rib)

Single box and multi-chamber: it is rarely used, and the middle belly plate has little influence on the torsional rigidity of the steel box girder.

Double box steel girder bridge

Scope of application: when the bridge width is large or the single box size, production, transportation, installation is difficult or the effective width of a single box is small and uneconomical.

Beam setting: Can be set or not set (see photo below)

Multi-box steel girder bridge

Scope of application: when the span is small and the bridge width is large.

The main beam is arranged as uniformly-spaced as possible: made the main beam force is uniform.

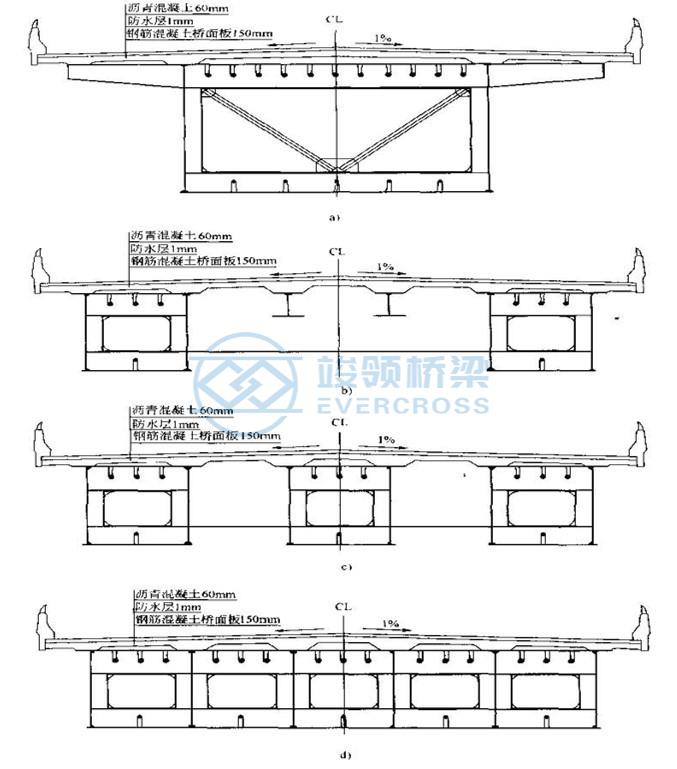

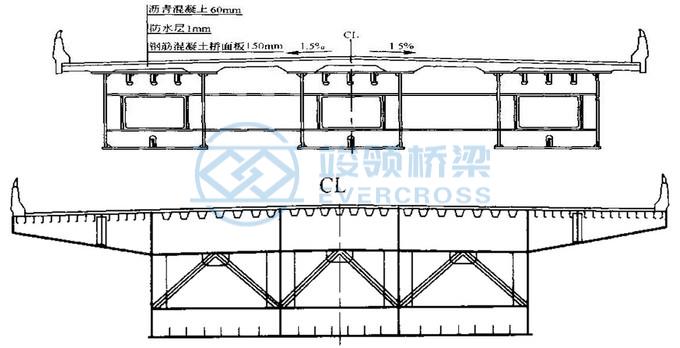

The proportion between the height of girder and width of bridge of flat steel box-girder bridge.

It is mainly used as a stiffening beam for suspension bridges, cable-stayed bridges and arch bridges, etc., and the beam bridges are rarely adopted.

It is mainly used for suspension bridges in the past because of its large torsional and bending inertia and good wind resistance.

The top plate and bottom plate are usually reinforced with U-shaped longitudinal ribs

There is no intermediate web inside the box, and the transverse partition spacing is small

Transverse diaphragms usually adopted solid-web.

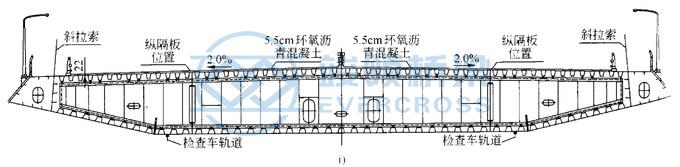

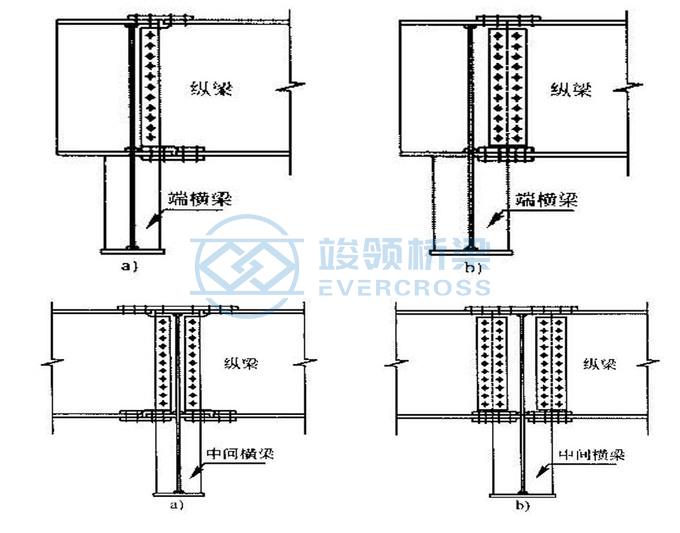

Connecting plate, bulkhead, longitudinal stiffener and transverse stiffener

Longitudinal beam

Effect

When the main beam spacing is large, the span of the reinforced concrete bridge panel should be reduced;

Improve the stiffness of steel bridge panels.

Structure

Longitudinal beam spacing: for reinforced concrete bridge panels, not more than 3m.

For steel bridge panels, when the beams or transverse ribs spacing is small, it could not set.

When the bridge width is large, it can be set.

(3) Beam

Effect

For two or more boxes, made the main beam stressed evenly

Support longitudinal beams or bridge panels

The end beam can effectively improve the overall torsional resistance of the bridge and disperse the fulcrum reaction.

Interval

When there is a longitudinal beam, it is not greater than 6m. (reduce longitudinal span)

Without a longitudinal beam, the maximum value is 20m. (mainly plays the role of lateral load distribution)

When there is a longitudinal beam, it is not greater than 6m. (reduce longitudinal span)

Without a longitudinal beam, the maximum value is 20m. (mainly plays the role of lateral load distribution)

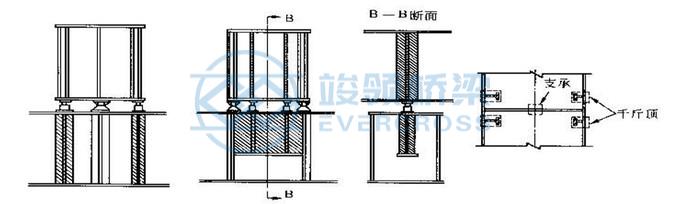

(4) Support and temporary fulcrum arrangement

Two supports should be installed at the end of a single-box steel beam bridge to ensure structural stability and resistance to torque

Multi-box steel beam bridge, one steel box and one support.

When a steel box is equipped with multiple supports, the bearing force may be uneven.

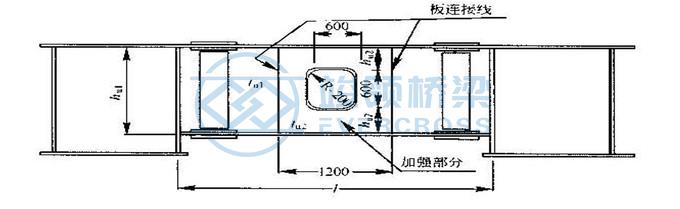

Temporary fulcrum supporting the jack should be provided to strengthen the structure.

3. Mechanical characteristics and structural measures of steel box-girder bridge:

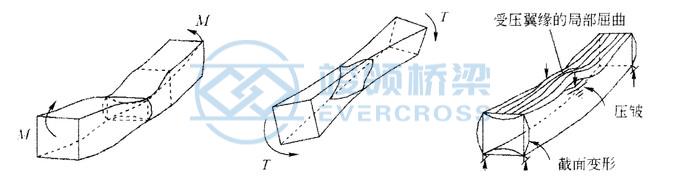

(1) Damage type

Under the action of bending moment, the compression flange is partially unstable and occurs bending failure.

The box girder is distorted under the action of torque

Under the action of concentrated force, the nearby beam web was crumpled failure.

(2)Structural measure

Should be provide adequate transverse partitions to avoid distortion and lateral bending

Should be provide enough stiffening ribs to prevent the local instability of the compression flange.

Should be arrange a certain stiffening rib in order to prevent local compressive stress or out-of-plane bending in the process of making, transporting and installing the tension flange.

Transverse ribs and longitudinal ribs should be set up to prevent the buckling of web and local creasing.

Structural characteristics of Steel box-girder bridge:

Application of of steel box-girder bridge:

Road, rail and high-speed rail

Advantages of steel box-girder bridge compared with truss girder bridge:

Light weight, save steel

High flexural and torsional stiffness

Quick installation and easy maintenance

Suitable for forming continuous beams

Novelty structure, the shape is simple and beautiful

Advantages of steel box-girder bridge:

The flange width is large, with great bending resistance and large span;

Large torsional stiffness, uniform lateral load distribution, suitable for curved bridge;

The transverse flexural stiffness is large, the horizontal resistance is strong, and the longitudinal connection can be saved, and the single box can also save the transverse connection.

The single box girder has good overall stability and fast construction;

Small beam height, suitable for overpasses and bridges with limited building height;

Beautiful appearance, transverse and stiffening structure are in the box;

The box is hollow structure, easy to arrange ancillary facilities, repair and maintenance.

Evercross Steel Bridges Overview:

EVERCROSS STEEL BRIDGE SPECIFICATION | |

EVERCROSS STEEL BRIDGE | Bailey bridge (Compact-200, Compact-100, LSB, PB100, China-321, BSB) |

DESIGN SPANS | 10M TO 300M Single span |

CARRIAGE WAY | SINGLE LANE, DOUBLE LANES, MULTILANE, WALKWAY, ETC |

LOADING CAPACITY | AASHTO HL93.HS15-44, HS20-44, HS25-44, |

STEEL GRADE | EN10025 S355JR S355J0/EN10219 S460J0/EN10113 S460N/BS4360 Grade 55C |

CERTIFICATES | ISO9001, ISO14001, ISO45001, EN1090, CIDB, COC, PVOC, SONCAP, etc. |

WELDING | AWS D1.1/AWS D1.5 |

BOLTS | ISO898, AS/NZS1252, BS3692 or equivalent |

GALVANIZATION CODE | ISO1461 |

Certified

Certified