Steel Plate Girder Bridge

Steel plate girder Bridges Introduction:

Steel plate girder bridge is a bridge composed of steel plates welded, bolted or riveted to form a solid belly steel beam as the main bearing structure, and the cross section is mostly I-shaped.

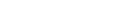

Composition of steel plate girder bridge

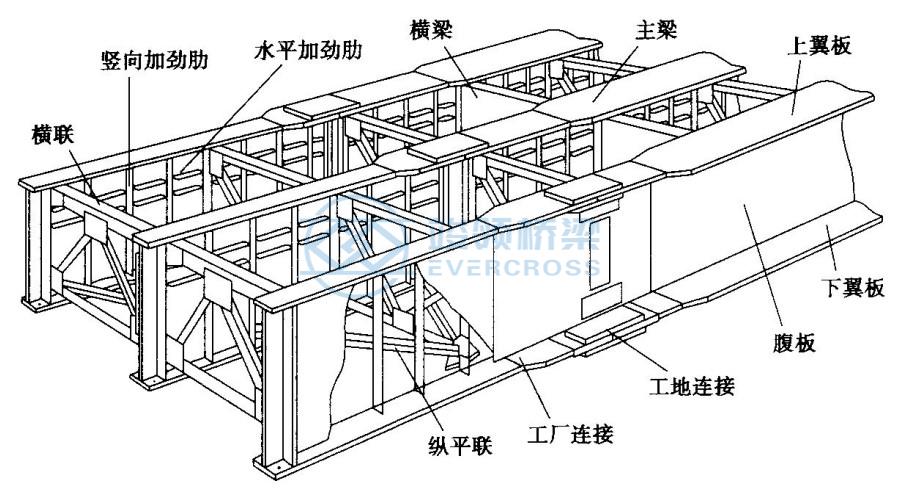

Form of the transverse connection

Classification of steel plate girder Bridges:

According to the driving mode, it is divided into: upper bearing plate beam and bottom bearing plate beam;

According to the connection: riveted plate beam, fully welded plate beam and bolted welded plate beam.

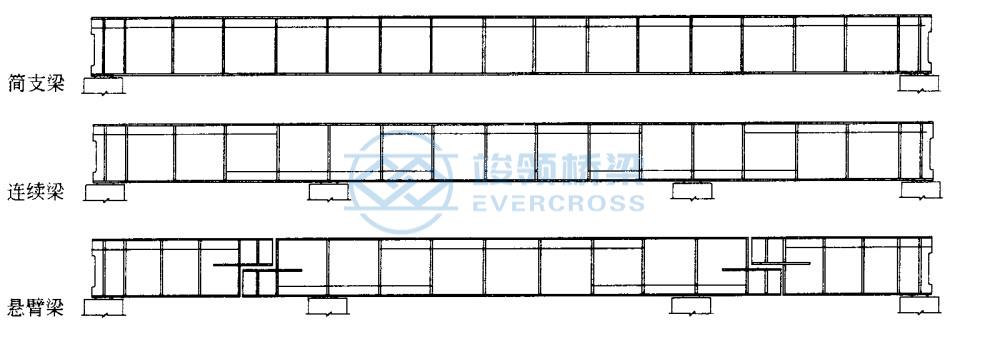

The economic span of simply supported steel plate girder bridge is generally below 40m, and the economic span of continuous steel plate girder bridge can reach 60m.

According to the bridge floor position

(1)Upper bearing steel plate girder bridge:

1.Composition of upper bearing plate and beam

Load-bearing structure (main beam), bridge floor, connecting system, support; No road and bridge structure (deck system). Among them: load-bearing structure (main beam) : composed of two I-beams; Bridge deck: bridge pillow, track, guard rail, fender, hook bolt composition; Connection system: upper horizontal longitudinal link, lower horizontal longitudinal link, cross link, cross brace composition.

The upper structure of the upper bearing steel plate girder bridge mainly includes: kingbeam、bracing、Bridge floor、support.

The bridge deck is located on the upper flange of the main beam

Longitudinal connection bridge deck system

The main load-bearing structure is composed of two steel plate beams, which mainly bear vertical loads.

The small span can be used equal section beam. The large span can be used variable section beam.

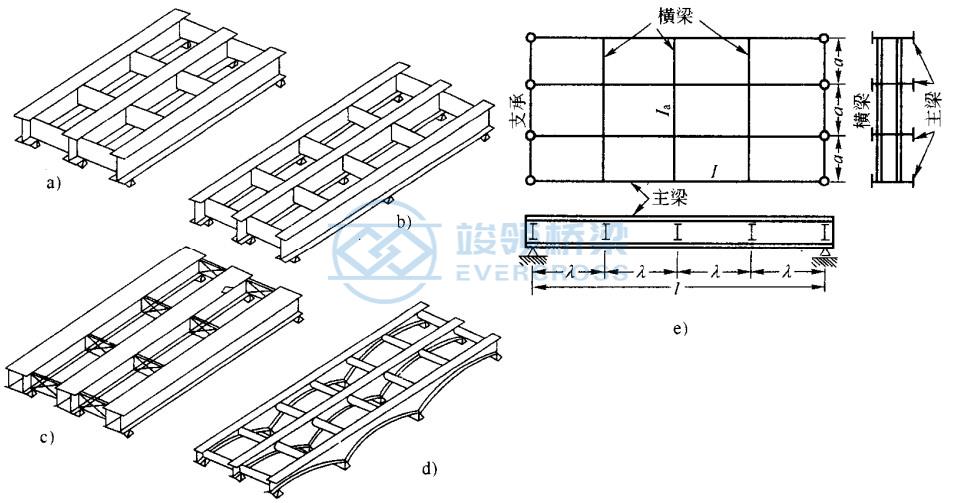

The vertical stiffener and horizontal stiffener are set at the same time to ensure the local stability of the web.

The vertical stiffener at the end of the beam is called the end stiffener, which transmits the beam end reaction force.

Composition and cross section of upper bearing plate girder bridge

The main beam、the upper horizontal longitudinal connection、the lower horizontal longitudinal connection

Composition of plate girder bridge surface with upper bearing

Characteristics and scope of application of upper bearing plate girder bridge:

Simple structure, save steel, can be transported in the whole hole, the whole hole erection, often used to small span

When the span is less than 40m, the steel plate girder bridge is more economical than the steel truss bridge, so the small-span steel bridge is commonly used as a plate girder bridge.

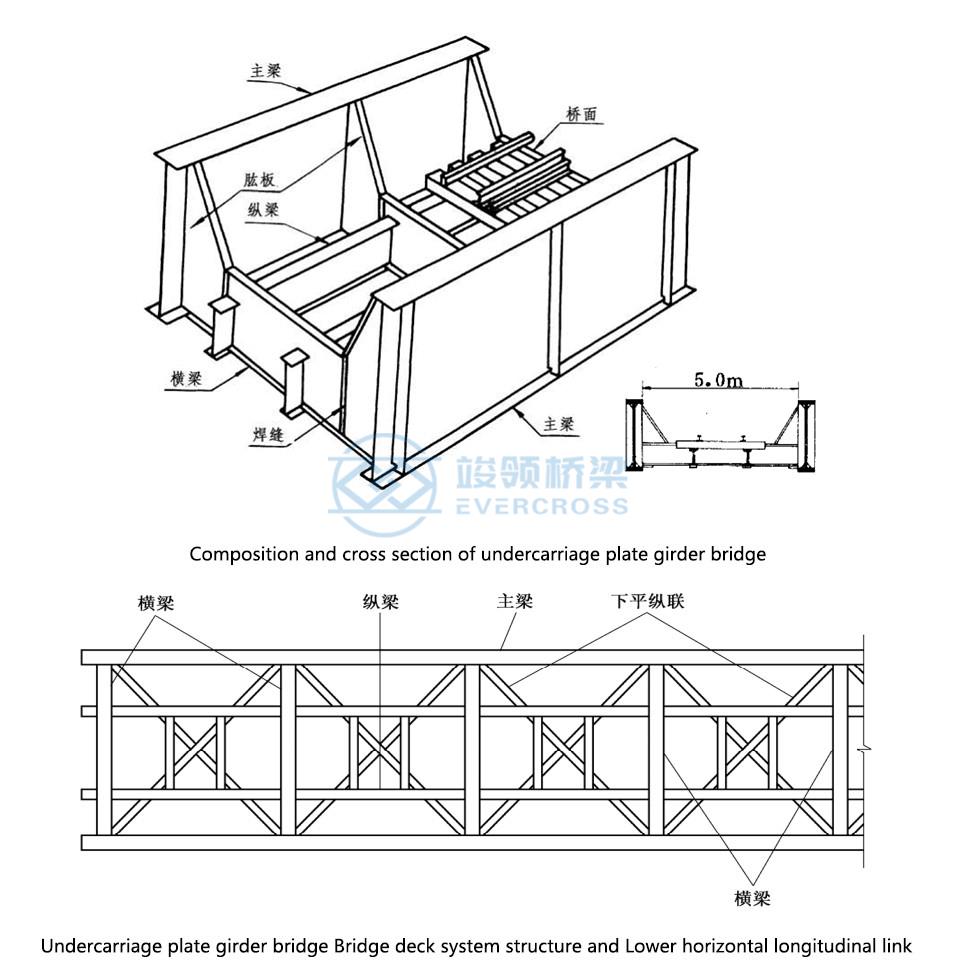

(2)Undercarriage steel plate girder bridge:

Composition of Undercarriage steel plate girder bridge:

Load-bearing structure (main beam), bridge deck, connecting system, bridge deck system, support. Load-bearing structure (main beam) : Composed of two I-beams, the center distance of the two main beams in standard design is 5.4m; The structure is the same as the upper bearing plate beam; Bridge deck: bridge pillow, track, rail, fender, hook bolt composition, structure with the upper bearing plate beam;

The bridge deck is located at the lower flange of the main beam.

Undercarriage plate girder bridge Bridge deck system structure and Lower horizontal longitudinal link

Characteristics and application range of undercarriage plate girder bridge

Building height (from rail bottom to beam bottom) is low;

Use more materials (increase the bridge floor system) and manufacturing also cost labor;

Because of the width, it cannot be transported in the whole hole, which increases the workload of loading and framing.

Scope of application: railway steel plate beam and highway steel plate beam

Features:

① The components are particularly suitable for manufacturing by industrial methods, easy to transport, and the installation speed of the site is fast, so the construction period of the steel bridge is short

② Steel Bridges are easy to repair and replace after damage

③ The weather resistance is poor, easy to rust, and the noise is large and the maintenance cost is high when the railway steel bridge adopts the open deck.

Advantages of Steel plate girder bridge:

Simple structure

Easy production

Whole hole transportation

Convenient installation and maintenance and maintenance

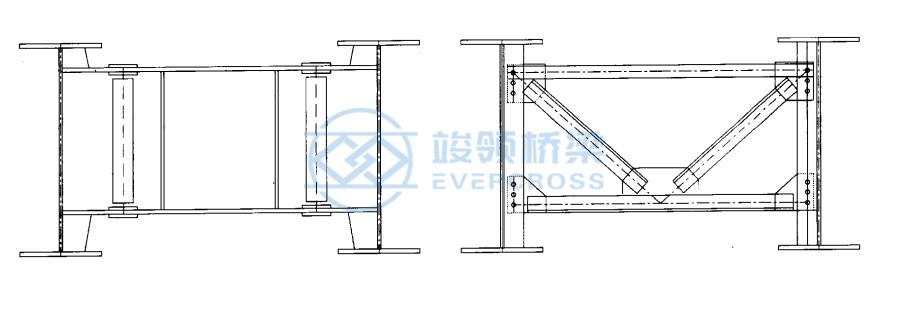

Evercross Steel Bridges Overview:

EVERCROSS STEEL BRIDGE SPECIFICATION | |

EVERCROSS STEEL BRIDGE | Bailey bridge (Compact-200, Compact-100, LSB, PB100, China-321, BSB) |

DESIGN SPANS | 10M TO 300M Single span |

CARRIAGE WAY | SINGLE LANE, DOUBLE LANES, MULTILANE, WALKWAY, ETC |

LOADING CAPACITY | AASHTO HL93.HS15-44, HS20-44, HS25-44, |

STEEL GRADE | EN10025 S355JR S355J0/EN10219 S460J0/EN10113 S460N/BS4360 Grade 55C |

CERTIFICATES | ISO9001, ISO14001, ISO45001, EN1090, CIDB, COC, PVOC, SONCAP, etc. |

WELDING | AWS D1.1/AWS D1.5 |

BOLTS | ISO898, AS/NZS1252, BS3692 or equivalent |

GALVANIZATION CODE | ISO1461 |

Certified

Certified