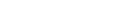

Structure and construction of type 321 Bailey plate

The Type 321 Bailey is welded with upper and lower strings, vertical and oblique rods. The upper and lower strings have convex and concave joints at the ends, and the truss is connected to the pin holes in the joints. The string of the Bailey string consists of two No. 10 channels (back to back).

On the lower string, there are several steel plates with round holes, and both the upper and lower strings have reinforced strings and double stringers.Bolt holes are connected, and there are four bolt holes for connecting the support frame in the upper chord. The two holes in the middle are used to connect two or more rows of trusses and the same joints. Two holes at the end are used to connect the sections. When multiple rows of casing are used as beams or columns, the joints of the upper and lower Bailey plates must be reinforced with support frames.

On the lower chord, there are four beam plates with a tenon to hold the beam in place on the plane, and two elliptical holes in the channel web at the end of the lower chord. Used to connect the storm bar. The Bailey panel vertical bar is made of 8 I-beams with square holes on one side of the lower chord of the vertical bar for securing the beam through the beam clamp.The type 321 Bailey sheet is made of 16Mn, each weighing 270kg. The “321″ steel bridge is a prefabricated highway steel bridge. Its biggest features are: compact structure, easy disassembly, adaptability, can be quickly built with simple tools and manpower.

It is suitable for 5 kinds of loads such as car-10, car-15, car-20, belt type -50, trailer -80, etc. The bridge floor width is 3.7 meters, which can be combined into a variety of span simple support Bridges, ranging from 9m to 63m, and can be continuously constructed.

Certified

Certified